Cutting edge manufacturing on the world stage

ANCA took an early view to look beyond Australia’s shores whilst developing advanced manufacturing technologies now viewed as ‘business as usual’

When Pat Boland and Pat McCluskey first started Melbourne-based company ANCA in 1974, the fax machine was beginning to revolutionise communication and prompting a step change in how businesses viewed global expansion opportunities. Now ANCA are using their own servo technology to design and build a machine capable of manufacturing at a resolution of nanometre at their Australian headquarters.

Unlike many of their manufacturing peers, the co-founders decided at the outset the future of their company lay in exporting to the world. Fifty years later, ANCA is a globally recognised advanced manufacturer of precision tool and cutter-grinding machines, motion controls and sheet metal manufacturing equipment and software.

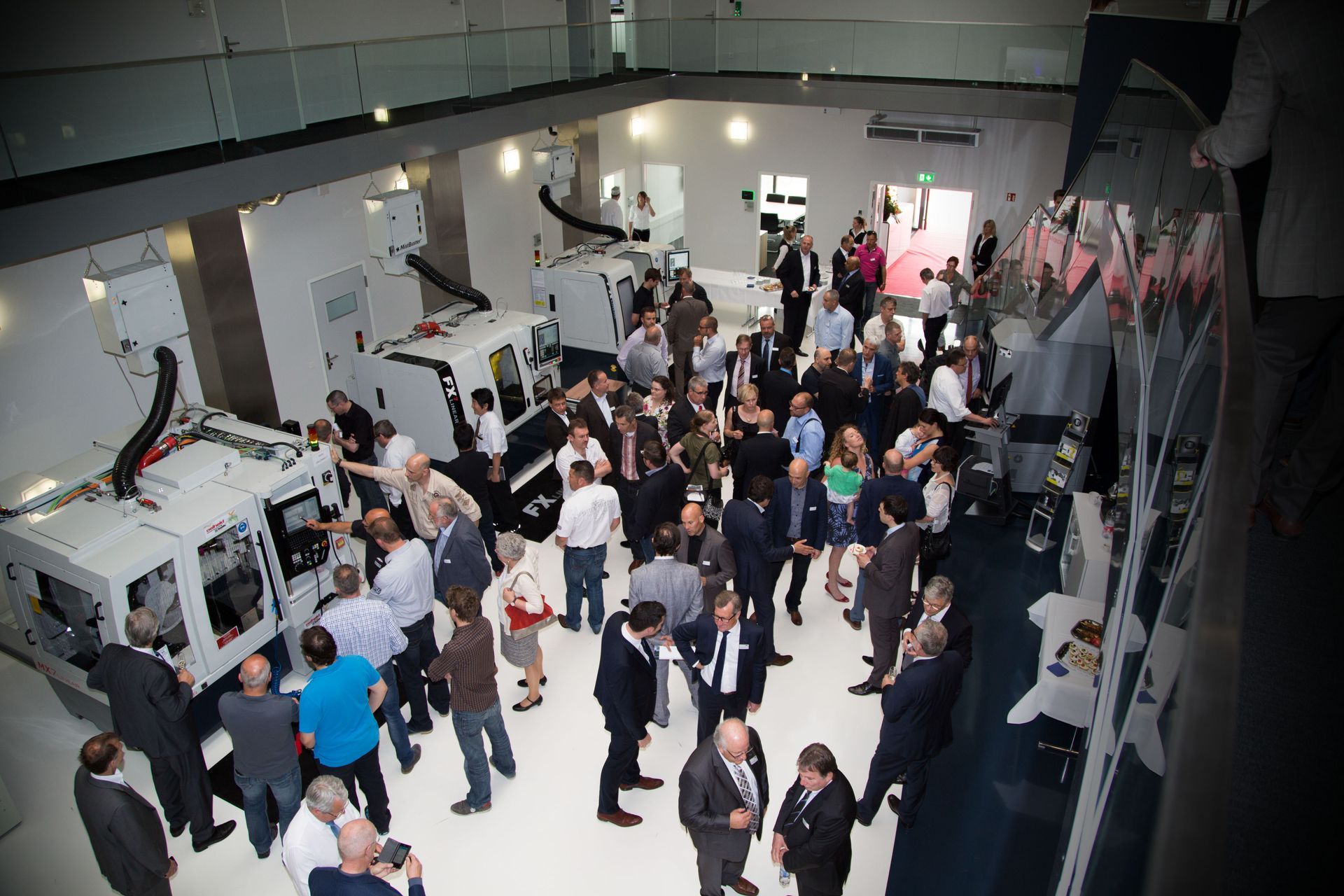

Simply, ANCA make machines which manufacture cutting tools. Their high-quality tool and cutter grinders are used by most major cutting tool manufacturers around the globe supplying sectors such as the aerospace, automotive, electronic, medical and other technologically advanced industries.

“We started with the view of delivering a highly sought-after product with a point of difference and realised early on the importance of being globally local – a good local support structure and sales team have been key to our success,” Boland explains.

ANCA now exports to over 50 countries, with the biggest markets in Europe, Asia, China and USA. ANCA’s longstanding global interaction has also resulted in a significant contribution to the local economy and those in our region.

“A significant contribution has been apprentice training centres in Melbourne and Thailand, which has resulted in a steady flow of apprentices into the sector.

“Through the years we have also collaborated with Australian universities and provided PhD scholarships, of which many of these graduates now work within our company in R&D and managerial roles. ANCA is rare locally in offering a chance for talented & ambitious people interested in advanced technology to contribute to world-leading manufacturing innovations.”

Over the decades, ANCA has also been forward-thinking about its environmental impact. It was, for example, an early adopter of wind power to power factories in Melbourne and has installed solar on factory roofs.

With over 1200 staff globally and an annual turnover of $300 million, they also have a rich history of world firsts including the first to introduce a modem for the support and diagnosis in a computer numeric control tool and cutter grinder.

Boland and McCluskey have shown that an Australian company can compete and innovate on a global scale with dozens of patent applications globally in the fields of mechanical engineering, electrical engineering and software. Boland is particularly proud of a patent for the balancing of grinding wheels which differentiates ANCA from its competitors.

Another recent patent registered in the USA controls the temperature of the spindle thus improving the stability of the machine. “Any temperature change will cause dimensional change which affects the accuracy of the final product produced.”

In 2022, Boland and McCluskey were inducted into the Honour Roll of the Victorian Manufacturing Hall of Fame for their service to the industry. "It is great to get recognition from our peers and formal recognition is important to put the spotlight on what local innovation is capable of which helps to inspire the next generation of innovators,” Boland says.

Looking to the future, ANCA is actively pushing for digitalisation of the factory shop floor. Already most of their machines are equipped with robots to load the parts. Next, they will deliver automation of the whole process, from the material and information flow into the machines, and the measuring systems.